Introduction

In various manufacturing, packing, and metalworking sectors, slitting cutters are important tools. Selecting the appropriate slitting cutter (also known as a slitting saw cutter) can significantly impact cut quality, process efficiency, and tool life, regardless of whether you're cutting copper, stainless steel, aluminum, flexible films, or steel coils.

In this blog, we will discuss:

- What a slitting cutter is

- Key types (HSS, carbide, etc.)

- How to choose the right one

- Maintenance & edge life

- Applications & industries

What is a Slitting Cutter?

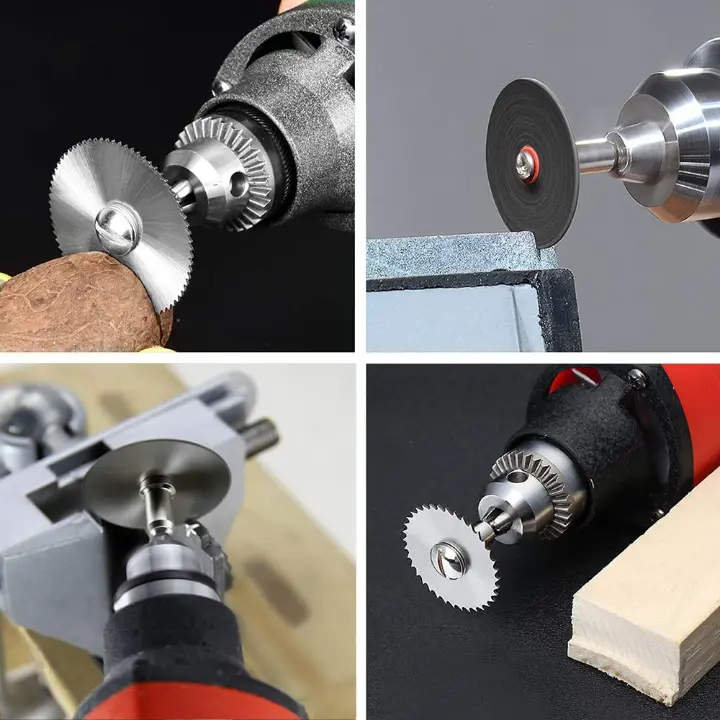

The purpose of a slitting cutter is to "slit" or cut wide materials into narrower strips using a rotating cutting tool, usually in the shape of a circular disc. These could be coils, films, foils, sheet metals, or other materials. The technique is often performed with accuracy and frequently in high-volume production. Slitting machines and slitter-rewinder systems also include some slitting cutters.

Types of Slitting Cutters

The following are standard types, along with advantages and disadvantages:

|

Type |

Material / Features |

Best Use Cases |

Pros |

Cons |

|

HSS Slitting Cutter (High Speed Steel) |

Can be different grades (e.g. M2, M35, etc.), sometimes coated for wear resistance. |

Good for general metal cutting, mild steel, stainless, where speed isn’t extremely high. |

Tough, more forgiving, relatively less expensive. |

Wears faster than carbide under high speed / abrasive materials, may need frequent sharpening. |

|

Carbide Slitting Cutter |

Solid carbide or carbide‑tipped, sometimes with coatings like TiAlN, etc. |

High speed cutting, abrasive or harder materials, tight tolerances. |

Long tool life, high cutting speed, crisp finish. |

More expensive, brittle compared to HSS, needs careful handling. |

|

Coated vs Uncoated |

Coatings like TiN, TiCN or similar to reduce wear, heat. |

When you want longer life or cutting under tougher conditions. |

Better wear resistance, can handle heat. |

Costlier; if coating fails, performance drops. |

|

Custom / Specialty Cutters |

Special tooth profiles, special thickness, very thin or very large diameter, cryo‑treated, |

When standard sizes won’t work, or for high precision, special materials. |

Fit specific needs, can yield better performance. |

Lead time, cost, sometimes limited suppliers. |

Key Specifications to Consider

These are the factors you should consider when selecting a slitting cutter:

- The materials need to be cut: copper, brass, aluminum, mild steel, stainless steel, plastic films, etc. Wear, heat, and friction loads are imposed differently by different materials.

- The strip's thickness: How narrow is the strip, and how thick is the material you want to cut? Different cutter widths and tooth designs are required for very thin and very thick strips.

- Diameter and Bore Size: Inner hole (bore) to attach to the arbor, cutter diameter. must be compatible with the machine's configuration.

- Number of teeth and tooth profile: Fewer teeth may allow for greater chip removal, while more teeth often result in a smoother finish but may require slower feeding.

- Coating & Heat treatment: To prolong durability, reduce off wear, and keep the edge at high speeds. This type of therapy is applied to certain cutters.

- Tolerance and edge quality: Tight tolerances are required if you require precision slitting, such as for electronics or foils.

Applications & Industries

Many industries use slitting cutters; here are a few examples:

- Steel & Metal fabrication: Used to cut coils of aluminum, stainless steel, and steel into thin strips.

- Packaging sector: BOPP, PET, PE, laminated materials, foils, slitting films, etc.

- Manufacturing Electronics & Batteries: cutting copper and aluminum foils.

- Automotive: Components, trims, decorative finishes, etc.

- Textiles / Non-woven materials: include plastic films and slitting textiles.

- Print, label, and adhesive tape industries: For precise cutting of flexible materials.

Maintenance, Best Practices & Troubleshooting

Use the following advice to extend the life and performance of slitting cutters:

- If using in slitting machines or slitter rewinder setups, maintain appropriate tension management. Poor edge finish and vibration are caused by loose tension.

- Depending on the material and type of cutter, use the appropriate feed rate and speed. Don't put too much strain on the cutter.

- To help lower heat and extend cutter life, use cutting fluids or lubricants, particularly when cutting metal.

- To maintain a sharp edge, regularly replace (for carbide) or sharpen (for HSS).

- Make sure the machine is aligned properly; a poorly configured machine may wobble, chip, or wear unevenly.

- To prevent damage or distortion of thin blades, store cutters correctly.

Conclusion

A well-chosen slitting cutter can cut waste, save operating costs, and significantly enhance production quality. Knowing the material, cutter design, and maintenance needs is essential, whether you're searching for carbide for high speed, high accuracy work or HSS for general metal slitting.