One of the most commonly used machining methods is milling. Questions about milling, its various forms, and its operations are often asked by newcomers to the field. This article will discuss the milling technique in detail. It will provide useful information for both beginners and experts. It also gives a lot of advice on how to enhance the quality of milling operations.

What is Milling?

A rotating cutter is used in the milling process, which is a type of machining, to carefully remove material from a workpiece. Creating the desired shape in the workpiece is the goal of this subtractive manufacturing approach.

Modern milling machines often use computer numerical control (CNC) to automate process control.

The rotary cutting tool is the primary component of a milling machine. The material removal process is performed by this cutting tool. Both single-point and multi-point cutting tools can be used with milling machines. In milling, the cutting tool rotates perpendicular to the axis of rotation. For instance, the cutter moves in the X-Y plane when the cutting is rotating around the Z-axis in the X-Y plane.

What are the different steps in the milling process?

Here is a step-by-step breakdown of the working process of milling machines:

The material removal process begins when the workpiece and cutter connect at a rotating tangent.

- Workpiece loading: This first setup involves holding and fastening the workpiece on the machine table feed. Errors in machining and poor precision will result from uneven fixtures.

- Tool selection: There are many types of tools for milling machines. Choose the right tool for the job based on the material of the workpiece and the desired result.

- Machine setup: This includes modifying variables such as feed rate, cutting depth, coolant flow, and spindle speed.

- Milling execution: After the setup is finished, the operator begins the actual milling process.

- Roughing: A considerable amount of material is removed from the workpiece during the roughing process. This is done in an attempt to make the workpiece somehow appears the preferred shape. For this, high feed rates and cutting speeds are used.

- Semi-finishing: After the roughing process, the spindle speed of the milling machine is reduced to remove finer material and improve the surface finish. The shape of the final part and the workpiece is the same.

- Finishing: Finishing is done with a small depth of cut and a very slow feed rate. The goal is to increase the dimensional precision of the part and bring it as close as the machine can.

- Unloading: The operator separate this final component from the milling machine.

- Inspection and quality control: The finished component is checked to ensure there are no defects. If there are any problems or more machining is required. After the part is loaded onto the machine, the operator performs another finishing pass. This step is repeated until the part meets the required requirements.

- Post-processing: The part may go through any additional machining that is required after milling. Grinding, cleaning, deburring, and surface treatment are typical post-processing techniques.

What are the Different Types of Milling Operations?

There are many types of milling processes. Each of these types is capable of producing components of different shapes. These are the following:

- End milling: Although it looks similar to a drill bit, the end mill offers greater versatility. It can cut not only in the axial direction like a drill, but also in the radial direction, allowing it to perform tasks such as side milling, slotting and profiling. Only axial cuts can be made with a drilling machine. Only radial cuts can be made with a conventional milling machine.

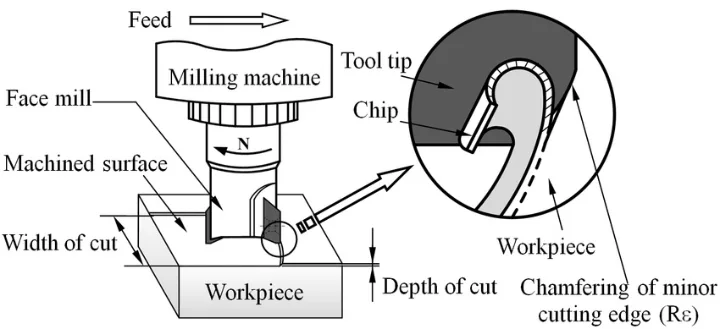

- Face Milling: When working on the surface of a workpiece, a face mill is used. An uneven surface can be made flat with a face mill. Additionally, an extremely smooth surface can also be obtained with it. For face milling, several options are available, including both manual and mechanized.

- Chamfer Milling: Chamfers and bevels are made with a chamfer milling machine. Another name for a chamfer mill is a chamfer cutter. A multipurpose tool, chamfer mill can also be used to make countersinks, detect holes, and deburr edges.

- Slot milling: In slot milling, grooves are made in the workpiece using a long rotary cutting tool. Its other name is groove milling. This machining method produces deeper grooves than the grooves made by end mills. There are several size options for closed or open grooves.

- Profile Milling: When machining vertical or vertically inclined surfaces, the profile milling process is used. It can be used in both roughing and finishing stages. In profile milling, several types of cutting tools are used based on the finishing or roughing operation.

- Helical Milling: The process of helical milling creates helical grooves, holes, and passages in a cylindrical object. There are rotating tables with workpieces. In helical milling, the rotating cutter moves along a helical path relative to the workpiece, allowing for the efficient and precise creation of smooth holes and channels. This method is commonly used for producing high-quality circular features with improved surface finish and dimensional accuracy.

- Thread Milling: Threads are created inside the workpiece through thread milling. Only pre-drilled pilot holes can be utilized with thread mills. In addition to rotating, the thread mill also rotates around its inner surface. Thread turning is used more frequently than thread milling.

- CNC Milling: Computer Numerical Control, or CNC, is the abbreviation for CNC milling. In CNC milling, computer programs are used to control the motion of cutting tools. This allows for the creation of complex pieces quickly. CNC milling machines come with a variety of axes to choose from, depending on the complex shapes.

Conclusion:

Milling is a basic machining procedure that offers versatility, accuracy, and a wide range of uses. From simple to advanced operations, understanding each step and choosing the right equipment can greatly improve quality and efficiency. With the rise of CNC milling, even complex shapes can be produced quickly and accurately. Mastering the process ensures superior results and keeps you competitive in modern manufacturing.