Carbide Slitting Saw DIN 1838 B

Carbide slitting saws are advanced circular cutting tools designed for high-precision slotting, grooving, & parting-off tasks in metalworking & machining. Crafted from solid tungsten carbide or carbide-tipped steel, they offer exceptional performance when cutting hard or abrasive materials. Their durability, dimensional accuracy, & ability to operate at high speeds make them ideal for demanding production environments.

Materials to cut : steel, cast, non-ferrous metals

Application: recommended for slotting & cutting materials which make longer chips, suitable for cutting thick-walled profiles (wall over 2 mm)

Machine: metal processing machine.

- Carbide circular slitting saw blades with rough teeth

- Hollow ground with a flange, standardly produced without driving pin holes and without a keyway

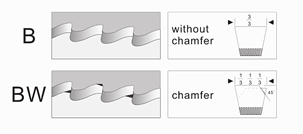

- Tooth form B (by request BW)

- Compared to type A chip clearance is reduced, which allows to remove chips away from cutting area efficiently

- Tolerances and hollow ground according DIN 1840

- High quality carbide slitting saw DIN 1838 B, designed especially for high performance.

- Carbide Circular saw blades for metal DIN 1838 B with rough teeth and teeth form B are recommended especially for cutting-off steels.

- In comparison with A tooth form they have much bigger chip clearance and they enable bigger cut. In standard modification the saw blades are made with hollow ground and with a flange.

- They can be ordered with BW tooth form (B tooth form with alternate chamfering).

Particularly for cutting off steels, circular saw blades for metal DIN 1838 B with rough teeth and teeth form B are advised. They allow for a larger cut and have a far greater chip clearance than a tooth shape. The saw blades in the standard modification have a flange and are hollow ground. BW tooth form (B tooth form with alternate chamfering) is an option for ordering them.

Carbide circular saw blades for metal DIN 1838 B - rough teeth

|

D (mm) |

50 |

63 |

80 |

100 |

125 |

160 |

200 |

250 |

315 |

|

dH7 (mm) |

13 |

16 |

22 |

22 |

22 |

32 |

32 |

32 |

40 |

|

B (mm) |

number of teeth |

||||||||

|

0,50 mm |

48 |

64 |

64 |

80 |

|

|

|

|

|

|

0,60 mm |

48 |

48 |

64 |

80 |

80 |

|

|

|

|

|

0,80 mm |

40 |

48 |

64 |

64 |

80 |

|

|

|

|

|

1,00 mm |

40 |

48 |

48 |

64 |

80 |

80 |

|

|

|

|

1,20 mm |

40 |

40 |

48 |

64 |

80 |

100 |

|

|

|

|

1,60 mm |

32 |

40 |

48 |

48 |

64 |

80 |

80 |

100 |

|

|

2,00 mm |

32 |

40 |

40 |

48 |

64 |

64 |

80 |

100 |

|

|

2,50 mm |

32 |

32 |

40 |

48 |

64 |

64 |

80 |

80 |

100 |

|

3,00 mm |

24 |

32 |

40 |

40 |

48 |

64 |

64 |

80 |

100 |

|

4,00 mm |

24 |

32 |

32 |

40 |

48 |

48 |

64 |

80 |

80 |

|

5,00 mm |

24 |

24 |

32 |

40 |

40 |

48 |

64 |

64 |

80 |

|

6,00 mm |

20 |

24 |

32 |

32 |

40 |

48 |

48 |

64 |

80 |