HSS Shell End Mill Cutters

HSS (High-Speed Steel) Shell End Milling Cutters are a type of milling tool designed for heavy-duty milling operations. They are typically mounted on an arbor and feature cutting teeth on both the circumference and at the bottom of the shell, making them ideal for removing large amounts of material quickly and efficiently. Shell end mills are suitable for machining large surfaces and can handle high feed rates.

- HSS (High-Speed Steel):The cutting teeth are made of high-speed steel, a material that maintains its hardness and sharpness at high temperatures, making it suitable for various materials like aluminium, steel, and stainless steel.

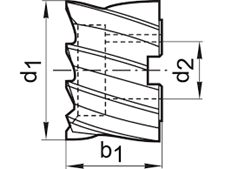

- Shell End Mill: Shell end mills are distinguished by their design, where the cutting teeth are located on the shell (the cylindrical body of the cutter) and the bottom of the shell, allowing for a wider range of cutting operations.

- Arbor Mounting: Shell end mills are designed to be mounted on an arbor, a shaft that connects the cutter to the machine tool.

- Heavy-Duty Operations: These cutters are specifically designed for heavy-duty milling tasks, such as roughing and profiling, making them suitable for removing large amounts of material.

- Versatile: They can perform a wide range of operations, including face milling, slotting, side milling, profiling, contouring, and chamfering.

- Materials: HSS shell end mills can be used on a variety of materials like aluminium, steel, stainless steel, and brass.

- Right-Hand or Left-Hand: Shell end mills can be either right-hand with a right-hand helix or left-hand with a left-hand helix.

Diameter Range: 40mm To 200mm.

Length Range: 40mm To 200 Mm.

Material: M-2, M35, M42.