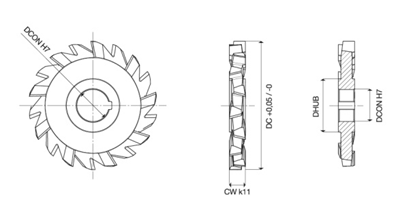

HSS Side & Face Cutter

Side and Face Cutters are designed with cutting teeth on its side as well as its circumference. They are made in varying diameters and widths depending on the application.

In face milling, only the top of the cutting tool does the milling action. However, in peripheral milling, the sides of the workpiece are involved too. Face milling can be done on machines with horizontal and vertical spindles while peripheral milling is limited to only machines with horizontal

HSS side and face milling cutter, DIN 138/885, with straight toothing for milling deep slots, cutting-off or cutting to length of steel and cast materials as well as short-chipping non-ferrous metals.

Basic Parameters:-

Type: (Type A Staggered Teeth & Type B Straigth Teeth)

Diameter Range: 50mm To 300mm, 2inches To 12inches.

Thickness Range: 4mm To 50 Mm.

Material: M-2, M35, M42.