HSS Slitting Saw DIN 1838 C

High quality slitting saw 1838 C, designed especially for high performance. The tooth consists of roughing tooth & finishing tooth. The roughing tooth is chamfered from both sides and in its cutting part is 0,15 - 0,30 mm bigger than the finishing one. Chips are cut into three parts and that´s why their chip removing is much more efficient. Perfect breaking prevents from blocking cutting area and it avoids poor tool life or even tool breakage due to the tooth clogging. It is recommended for cutting solid materials.

Cutting Materials: Steel, cast, non-ferrous metals

Application: Recommended for slotting and cutting materials which make longer chips, suitable for cutting thick-walled profiles (wall over 2 mm)

Machine: Metal processing machines

Characteristic:

- HSS circular saw blades with rough teeth

- Hollow ground with a flange, standardly produced without driving pin holes and without a keyway

- C tooth form consists of roughing teeth and finishing teeth

- The roughing tooth is chamfered from both sides and in its cutting part it is 0,15- 0,30 mm wider than the finishing one; the chips are cut into three parts & that´s why their chip removing is much more efficient

- Hollow ground according DIN 1840

Manufacturing Range: -

Diameter Range: 50mm To 300mm, 2inches To 12inches.

Thickness Range: .40 Mm To 20 Mm, 12 Thousand Onwards.

Material: M-2, M35, M42.

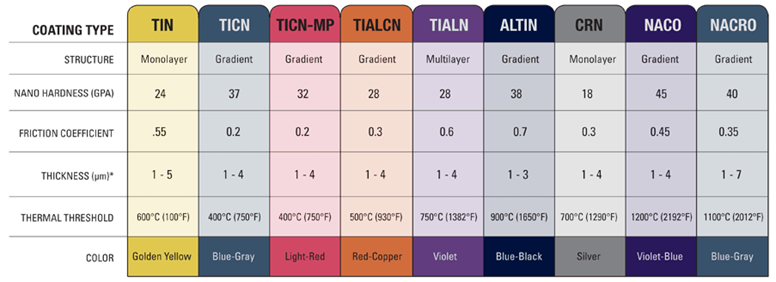

Coatings available:

Superior slitting saw 1838 C, specifically engineered for superior performance. India produces slitting saws.

There are two types of teeth: roughing and finishing. The roughing tooth is chamfered on both sides and is between 15 and 30 mm larger than the finishing tooth in its cutting section. Chips are broken into three pieces, which makes chip removal much more effective. Perfect breaking keeps the cutting area clear, preventing poor tool life or even tool damage from clogged teeth. For cutting solid materials, it is advised.