Carbide Center Drill

A carbide center drill is a specialized cutting tool used to create centering holes, typically a 60-degree cone, on the ends of shafts or workpieces. These drills are made from solid carbide, which provides high hardness, durability, and extended tool life.

- Carbide center drills are primarily used to create a 60-degree conical depression at the end of a workpiece. This cone serves as a guide for a tailstock center on a lathe, ensuring precise alignment and support during machining.

- Starting point for drilling: They also create a precise starting point for a larger drill bit, preventing the drill from "walking" or wandering during drilling.

- Carbide center drills are particularly well-suited for high-volume batch production due to their durability and extended lifespan.

- Hard materials: Their solid carbide construction allows them to be used on difficult-to-drill materials.

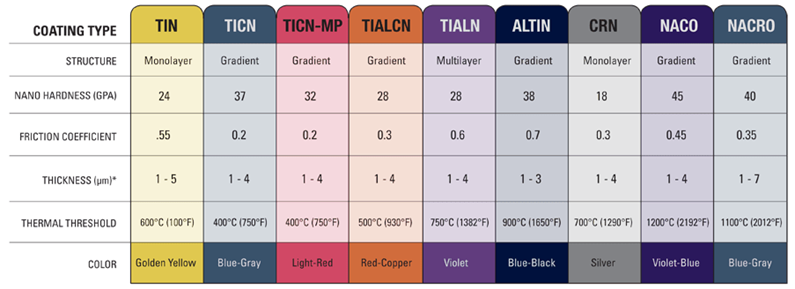

COATINGS AVAILABLE

Features:

- Solid carbide construction: This provides high hardness, durability, and resistance to wear, leading to extended tool life.

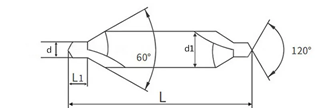

- 60-degree point: The standard angle of the center drill, matching the angle of lathe centers.

- Varied lengths and diameters: Available in various sizes to suit different workpiece needs.

OUR PRODUCTION RANGE CHART

|

d ( mm) |

d1 (mm) |

L ( mm) |

L1 (mm) |

|

1.5 |

4 |

36.5 |

2 |

|

2 |

5 |

41 |

2.6 |

|

2.5 |

6 |

44.5 |

3 |

|

3 |

8 |

50 |

4 |

|

4 |

10 |

57 |

5 |

|

5 |

12 |

64 |

6 |

|

6 |

16 |

70 |

8 |