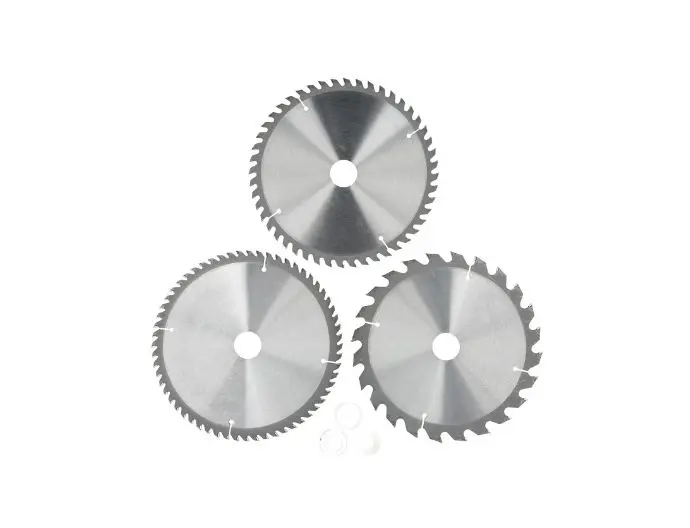

TCT SAW Blade

TCT blades, often referred to as "Tungsten Carbide Tipped" blades, are circular saw blades with tungsten carbide tips attached to the teeth. These tips, made from the hard material tungsten carbide, enhance the blade's durability, sharpness, and longevity, making them suitable for a variety of cutting tasks, especially in woodworking and metalworking.

Here's a more detailed explanation:

What they are:

Tungsten Carbide Tips:

The key feature of TCT blades is the tungsten carbide tipped teeth. Tungsten carbide is a very hard and wear-resistant material, allowing the blades to stay sharp for extended periods.

Various Applications:

TCT blades are commonly used in woodworking for cutting various types of wood, including hardwoods, softwoods, and engineered wood products. They are also used in other industries for cutting steel, pipes, and other materials.

Re-sharpening and Repair:

TCT blades are generally re-sharpenable, and individual tips can be replaced if damaged.

Benefits of using TCT blades:

Longevity:

TCT blades are known for their extended lifespan compared to standard saw blades.

Sharpness:

The tungsten carbide tips maintain a sharp edge for a longer time, resulting in clean and accurate cuts.

Durability:

The hard carbide material makes TCT blades resistant to wear and tear, reducing the need for frequent replacement.

Versatility:

They can be used on various materials, including wood, metal, and plastics.

Minimal Burr Production:

TCT blades are often preferred for materials like aluminum because they produce clean cuts with minimal burrs.

In essence, TCT blades offer a combination of durability, sharpness, and versatility, making them a popular choice for various cutting applications, particularly in woodworking and metalworking.

We Offer various Types of TCT blades as follows: -

1. Wood Cutting TCT Blades:

Designed for cutting various types of wood, including hardwood, softwood, and plywood.

2. Metal Cutting TCT Blades:

Designed for cutting steel and other ferrous metals, including rods, rebar, sheets, and pipes.

3. Aluminum Cutting TCT Blades:

Specifically designed for cutting aluminum, including bars, die-castings, extrusions, and sheet metal.

4. Multi-purpose Cutting TCT Blades:

Designed for cutting various types of plastic, offering a durable and efficient cutting experience.

By Tooth Configuration:

Crosscut Blades:

Designed for cutting across the grain of wood, producing a clean and precise cut.

Ripping Blades:

Designed for cutting with the grain of wood, producing a faster and more aggressive cut.

Combination Blades:

A versatile blade suitable for both ripping and crosscutting wood, offering a balance between speed and precision.

Fine-tooth Blades:

Designed for producing very smooth cuts, often used for finishing applications.

Other Considerations:

Blade Diameter: The diameter of the TCT blade must match the specifications of your saw.

Tooth Count: Higher tooth counts generally offer smoother cuts but may reduce cutting speed.

Blade Type: Consider factors like blade material, tooth geometry, and cutting application when choosing a TCT blade.