Carbide End Mill Cutters

End mill cutter is a cutting tool used in milling operations, primarily for machining hard & tough materials. It's made from solid carbide, offering high durability, precision, & wear resistance, making it suitable for various materials like steel, stainless steel, aluminum, & hardened metals.

Key Features and Advantages:

- Carbide end mills are known for their exceptional strength and resistance to wear, allowing them to cut through tough materials without chipping or dulling.

- High Speed and Efficiency: They can be run at higher speeds and feeds, enabling faster machining and increased productivity.

- Precision and Accuracy: Carbide end mills provide precise cuts and maintain dimensional accuracy, especially important for complex geometries.

- Wide Material Compatibility: They can be used on a variety of materials, including steel, stainless steel, aluminum, cast iron, and hardened steel

Common Applications:

- They are widely used in CNC machining centers for creating complex shapes and features.

- Milling Operations: Essential for milling, profiling, contouring, and slotting.

- Hard Material Machining: Specifically designed for working with hard and tough materials like hardened steel.

- Finishing and Semi-Finishing: Carbide end mills are used in both finishing and semi-finishing operations to achieve desired surface finishes.

Carbide end mills come in various types, categorized by their flute count, nose shape, and length. Common types include solid carbide end mills, ball nose end mills, corner radius end mills, roughing end mills, and indexable end mills.

Types of Carbide End Mills:

Flute Count:

- 2-flute: Suitable for general milling applications, especially on softer materials like aluminum.

- 4-flute: A good all-around choice for general milling.

- 5-flute and 6-flute: Offer higher chip removal and are well-suited for tougher materials or high-speed machining.

- Ball Nose: Used for creating rounded surfaces, pockets, and contours.

- Corner Radius: Designed to reduce the corner radius of cuts, providing better finish and productivity.

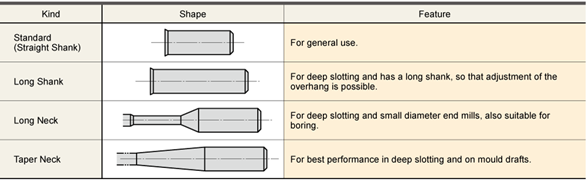

Length:

- Stub Length: Shorter tools with a shorter cutting length, ideal for applications where a longer tool isn't needed.

- Long Length: Reach into deeper pockets and cavities.

- Extra Long Length: For even deeper pockets and cavities.

Other Types:

- Roughing (Hog Mills): Designed for rapid material removal in roughing operations.

- Variable Index: Offers versatility by allowing the tool to be indexed and reused multiple times.

- Solid Carbide: Made from a single piece of carbide, offering high strength and durability.

- Indexable: Features replaceable inserts for cost-effective and long-lasting use.

- High Helical: Offers smoother cutting, especially for harder materials and high-speed machining.

- Square End Mills: Used for cutting straight walls and edges.

- Multi-Function Square End Mills: Offer versatility in various cutting operations.

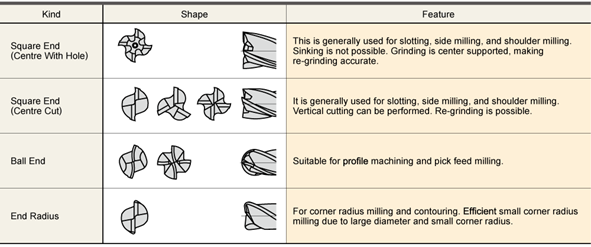

TYPES OF FLUTE SHAPE WISE

KIND OF FLUTE TOP SHAPE WISE

Coatings available