HSS End Mill Cutter

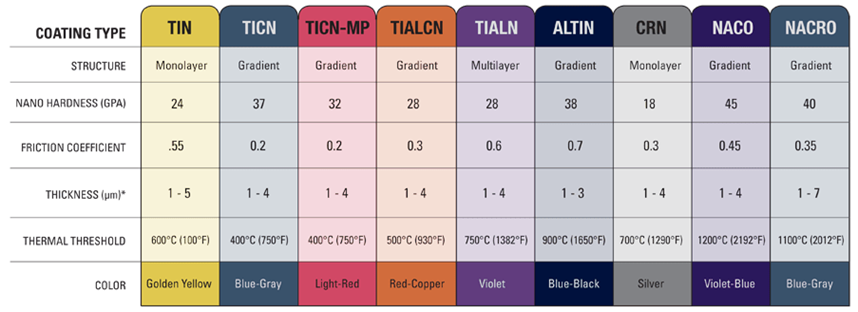

High-speed steel is used to make HSS end mill cutters, a type of milling tool used to machine a variety of materials, including general steel, brass, and aluminium. They are renowned for their durability, affordability, and post-polishing reusability. When stability is not an issue, HSS end mills are especially well-suited for machining. They can also be coated with PVD (Physical Vapour Deposition) coatings to boost cutting speeds and temperature resistance.

Key Features and Characteristics:

- HSS (High-Speed Steel) is a tool steel alloy known for its hardness, toughness, and wear resistance, making it suitable for high-speed machining applications.

- HSS end mills have cutting teeth on both the circumference and the end of the tool, allowing for versatile milling operations.

- They are commonly used for general milling, profile milling, tracer milling, face milling, plunging, contouring, slotting, drilling, and reaming.

Advantages:

- Cost-effective: HSS end mills are generally less expensive than tools made from more advanced materials like carbide.

- Toughness: They are less prone to breaking compared to some other tool materials.

- Reusability: Worn HSS end mills can be reused by polishing the cutting teeth.

- Cutting Speed: While HSS can handle high speeds, it may not be as durable or have as high a cutting speed as carbide, especially when machining harder materials.

- Variations:

- HSS end mills come in various forms, including those with and without PVD coatings, and HSS-PM (Powder Metallurgy) steel mills for increased wear and hardness.

- HSS end mills are frequently used for machining general materials on machines like MLTR (Metal Lathe, Turning, and Milling) machines at higher parameters than M2 end mills.

Coatings available