Efficiency and accuracy are essential for preserving a competitive edge in the fast-paced manufacturing world of today, particularly in the gear manufacturing industry. Gear hobbing is one of the best ways to make this process go more smoothly. Manufacturers can achieve remarkable accuracy and consistency while effectively reducing cycle times by utilizing top-notch gear hob cutters.

What is Gear Hobbing?

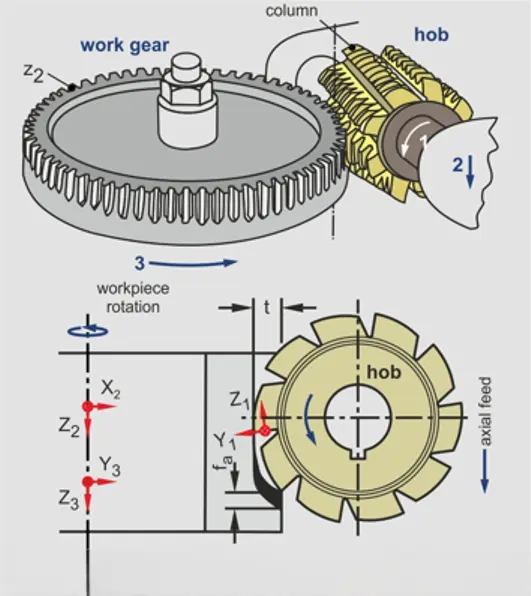

Gear hobbing is a machining technique that uses a specialized tool called a gear hob to cut gear teeth into cylindrical blanks. This process is perfect for making highly precise spur gears, helical gears, splines, and even worm gears.

Gear hobbing is a continuous process that offers more flexibility and efficiency than other gear production techniques. It is frequently utilized in industries where gear performance is crucial, such as automotive, aerospace, and industrial machinery.

The Role of Gear Hob Cutters

The key component of the gear hobbing operation is the gear hob cutter. Designed to endure the demanding requirements of high-speed and high-volume production, these cutting tools are composed of carbide or high-speed steel (HSS). Gear precision and surface finish are directly impacted by the hob cutter's geometry, coating, and quality.

Key Benefits of Using Quality Gear Hob Cutters:

- Higher Precision: Tight tolerances and uniform tooth profiles are guaranteed by sophisticated gear hob cutters.

- Faster Production: Increased production and shorter cycle times are achieved through optimized cutting speeds

- Longer Tool Life: Hob cutters with coatings, such as TiN and TiAlN, have a longer lifespan and need fewer tool changes.

- Cost Savings: Lower operating costs are the result of less tool wear and rework.

How Gear Hobbing Enhances Production Efficiency

1. Reduced Setup Time

With only minor modifications, gear hobbing machines can be quickly assembled. This is particularly advantageous for batch production, where downtime reduction is essential.

2. Consistent Quality

CNC-enabled automated hobbing procedures guarantee that every piece of gear satisfies exacting quality standards with minimal variance, reducing scrap and rework.

3. Versatility in Gear Types

By simply switching out the hob cutter, gear hobbing provides the versatility to produce several types of gears using the same machine, ranging from tiny precision gears to massive industrial gears.

4. Integration With Smart Manufacturing

Intelligent manufacturing systems can incorporate contemporary gear hobbing machines. Productivity and tool usage are further improved by real-time monitoring of cutting conditions and gear hob wear.

Choosing the Right Gear Hob Cutter

It's necessary to choose the appropriate gear hob cutter for your needs. Factors to consider include:

- Material of the workpiece

- Type of gear (spur, helical, spline, etc.)

- Desired gear quality grade

- Machine compatibility

Working with a reputable hob cutter manufacturer ensures access to technical support, custom tooling solutions, and replacement tools that keep your production line running smoothly.

Final Thoughts

Working with a trustworthy hob cutter manufacturer guarantees that you will have access to replacement tools, special tooling solutions, and technical assistance to keep your production line operating efficiently.

Whether you're scaling up production or aiming for tighter tolerances, gear hobbing with high-performance hob cutters is the solution that keeps your operations efficient and competitive.

Ready to boost your gear production? Contact our experts today to find the perfect gear hob cutter for your needs.