Carbide Slitting Saw DIN 1837 A

Carbide slitting saws, or solid carbide slitting saws, are high-performance cutting tools used in various industries to make precise slots and cuts in materials like steel, alloys, and even wood. They are known for their durability, ability to withstand high speeds, and longer lifespan compared to traditional saws.

Key Features and Benefits:

- Material: Made from solid carbide, a very hard and durable material.

- Precision: Used for making precise slots and cuts, often in CNC milling machines.

- Durability: Carbide is known to cut hard material and can withstand high tempratures

- High Speed: Can be used at high speeds without losing their edge.

- Applications: Used in various industries, including aerospace, automotive, and general manufacturing.

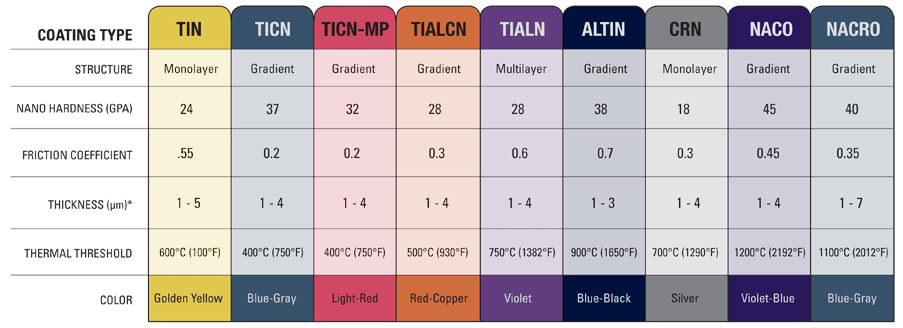

Coatings available

For slotting hard and delicate materials, circular saw blades for metal DIN 1837 A with fine teeth and a tooth shape are

Particularly for thin saw blades with a tooth pitch between 0.8 and 3.0 mm, a tooth shape is appropriate. The cutting edge is quite sharp. Longer chips cannot be effectively removed from the cutting area due to the decreased chip clearance. The slitting saw blades are typically modified to have a flange and hollow ground surfaces. They can be provided wth a keyway and AW tooth form (the tooth form A with alternate chamfering.

CARBIDE circular saw blades for metal DIN 1837A - fine teeth

| D (mm) | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 315 |

| dH7 (mm) | 5 | 8 | 8 | 10 | 13 | 16 | 22 | 22 | 22 | 32 | 32 | 32 | 40 |

| B (mm) | number of teeth | ||||||||||||

| 0,20 mm | 80 | 80 | 100 | 128 | 128 | ||||||||

| 0,25 mm | 64 | 80 | 100 | 100 | 128 | 160 | |||||||

| 0,30 mm | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||||

| 0,40 mm | 64 | 64 | 80 | 100 | 100 | 128 | 160 | ||||||

| 0,50 mm | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | |||||

| 0,60 mm | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | ||||

| 0,80 mm | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||

| 1,00 mm | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 | ||

| 1,20 mm | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | 200 | ||

| 1,60 mm | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 200 | 200 | |

| 2,00 mm | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 100 | 128 | 160 | 200 | |

| 2,50 mm | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 |

| 3,00 mm | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 160 | 160 | 200 |

| 4,00 mm | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 |

| 5,00 mm | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 |

| 6,00 mm | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 128 | 128 | 160 |