Introduction

Efficiency and accuracy are no longer optional in the fast-paced production industry; they are now necessary. The High-Speed Steel Slitting Saw (HSS) slitting saw, is a quiet hero among the different tools leading this precision revolution.

This small yet effective cutting tool is essential for anything from routine machine shop tasks to the manufacturing of aeronautical components.

What is an HSS Slitting Saw?

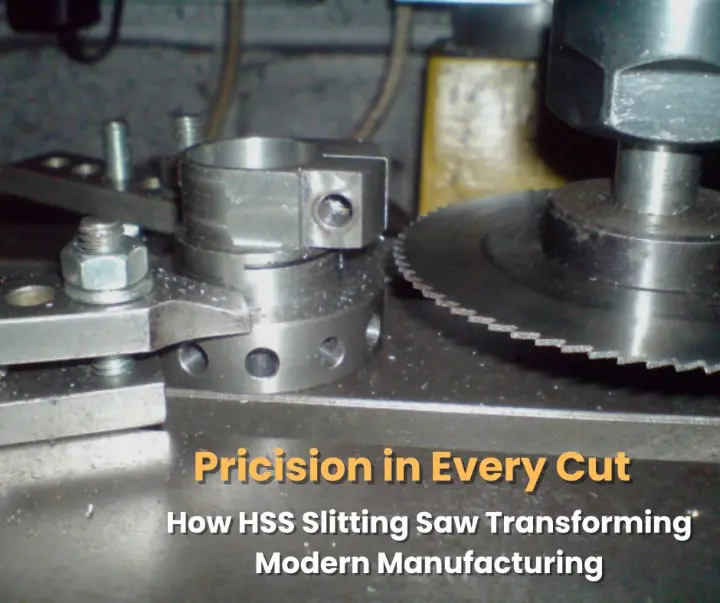

An HSS slitting saw is a thin, round blade made of high-speed steel—a material known for maintaining hardness even at high temperatures. These saws are made to cut small details, thin grooves, and slots in composite, metal, and plastic materials.

HSS slitting saws are a popular option for machinists who need both accuracy and a long tool life because of their robustness and resistance to wear.

Why Manufacturers Rely on HSS Slitting Saws

- Superior

Heat Resistance

High-speed steel retains its cutting edge even in harsh environments. This means fewer tool changes, a longer lifespan, and more efficient operations. - Exceptional

Versatility

HSS saws perform consistently on a wide range of materials, including stainless steel, aluminum, and brass. - Ensure

Clean& Accurate Cuts

The small tooth geometry ensures burr-free finishing and good repeatability—two key aspects in industries that require precision tolerances. - Cost

Efficiency

Compared to carbide tools, HSS slitting saws provide an outstanding mix of performance and cost.

Applications Across Industries

HSS slitting saws serve in a variety of industries, including automotive, aerospace, medical devices, and precision engineering, where reliability and dimensional accuracy are critical. They are typically used to cut keyways, slice thin portions, and separate components during final assembly.

How to Choose the Right HSS Slitting Saw

Choosing the best Slitting saw is based on a few essential factors:

- Material Type: Match the saw's composition and coating (such as TiN or TiAlN) to the workpiece material.

- Tooth Form & Pitch: Thinner materials require finer teeth, while thicker parts require coarser teeth.

- Cutting Speed & Feed Rate: Optimize settings to increase tool life and surface quality.

- Coolant Usage: Proper lubrication reduces friction and heat generation.

The Future of Precision Cutting

As CNC machining and automation expand, the role of traditional tools such as the HSS slitting saw change. Manufacturers are now pairing these saws with smart tooling systems, adaptive feed controls, and predictive maintenance software to improve accuracy and uptime.

Final Thoughts

In an industry preoccupied with innovation, it is easy to overlook the simple cutting tool. However, without the precision and dependability of the HSS slitting saw, modern production would not be possible. Whether you're a shop owner trying to improve productivity or a quality-conscious engineer, investing in high-performance slitting saws is a simple step that yields enormous rewards.